Pdca Act Action

The Iso 9001 15 Standard And The Plan Do Check Act Cycle Qualitywbt

Pdca Cycle Images Stock Photos Vectors Shutterstock

How To Use The Plan Do Check Act Pdca Method Successfully In The Home

The Plan Do Check Act Pdca Cycle Ppt Slide Powerpoint Presentation Slides Ppt Slides Graphics Sample Ppt Files Template Slide

Nems Plan Do Check Act

Plan Do Check Act Early Childhood Training And Technical Assistance System

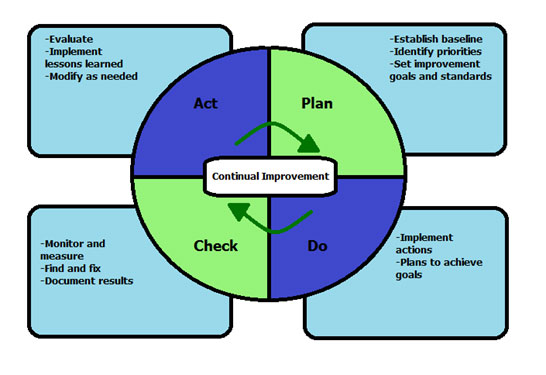

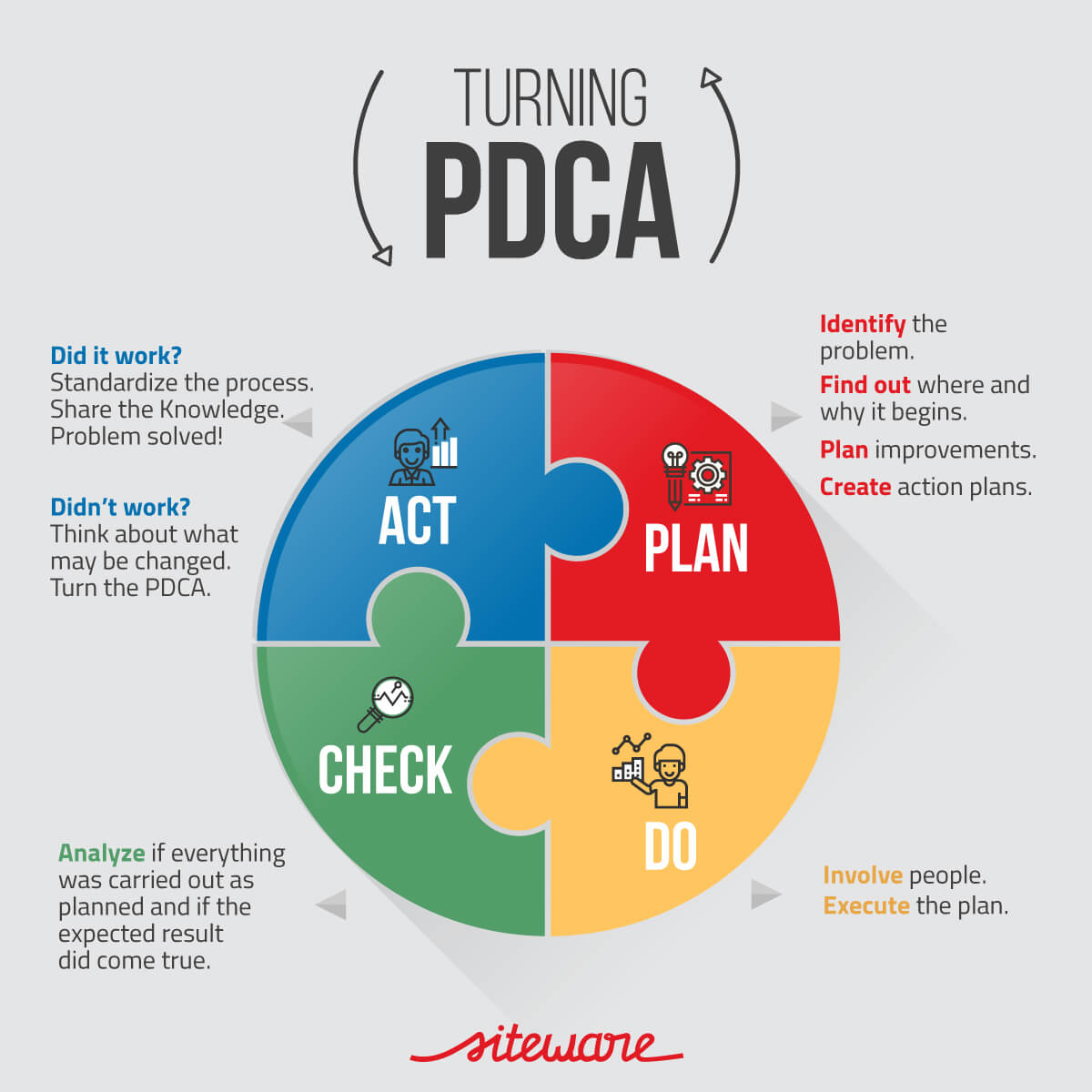

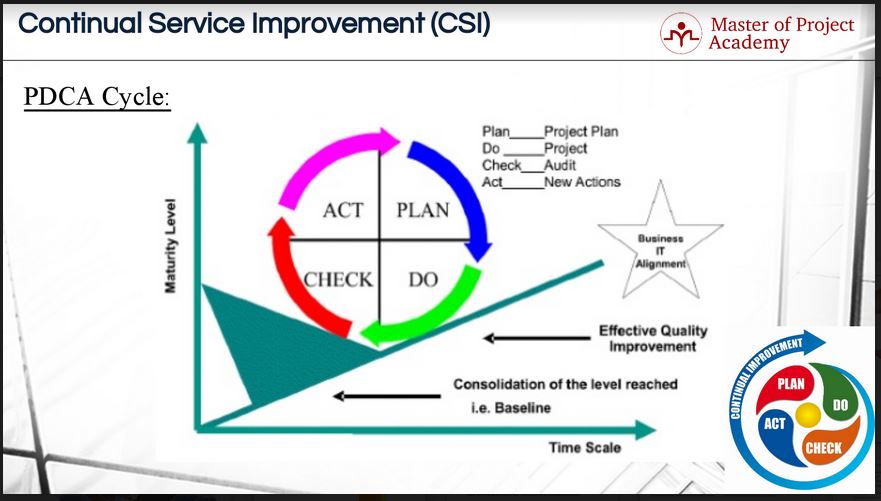

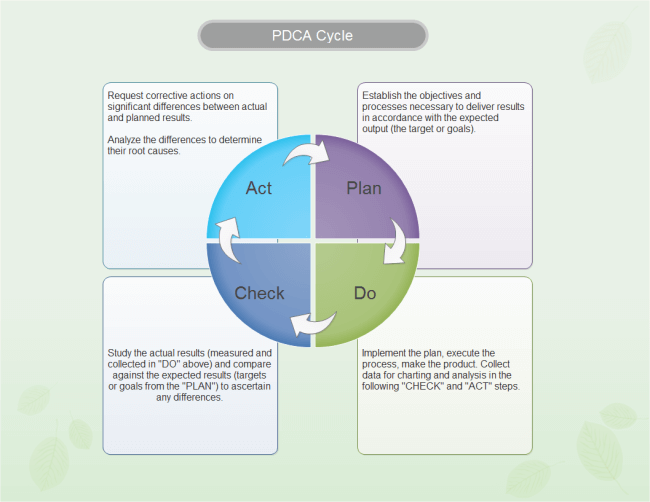

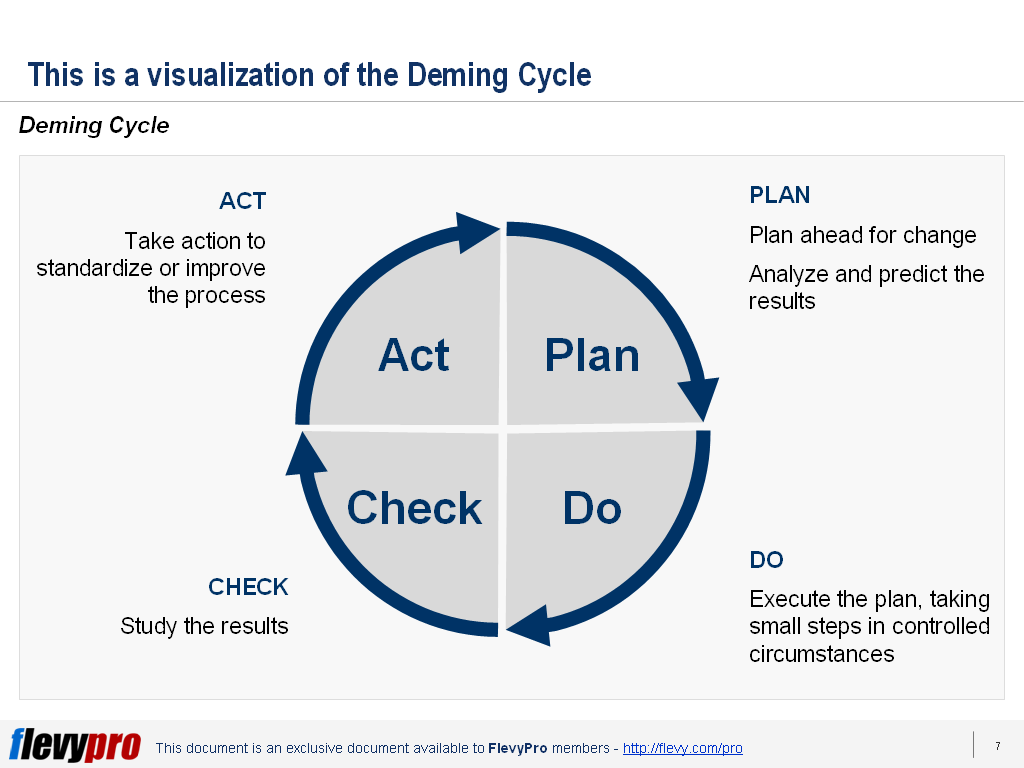

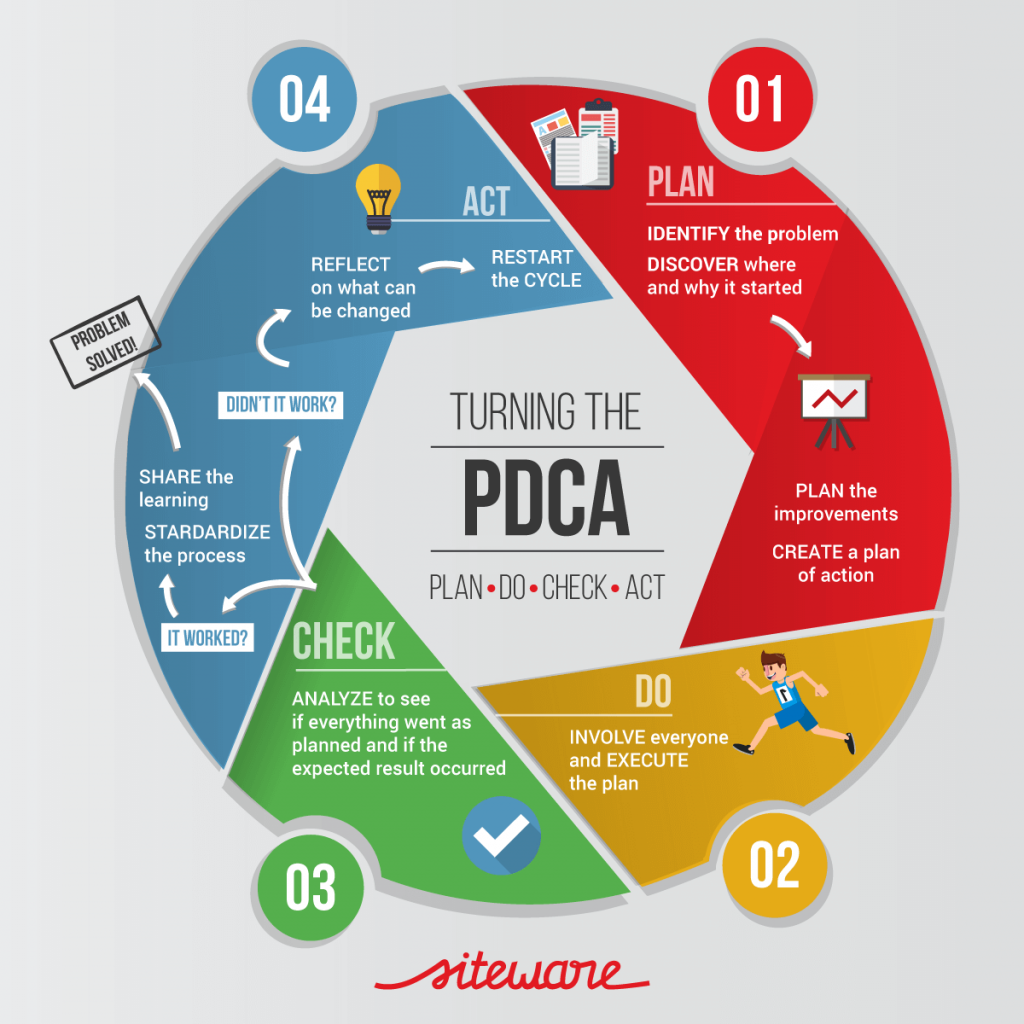

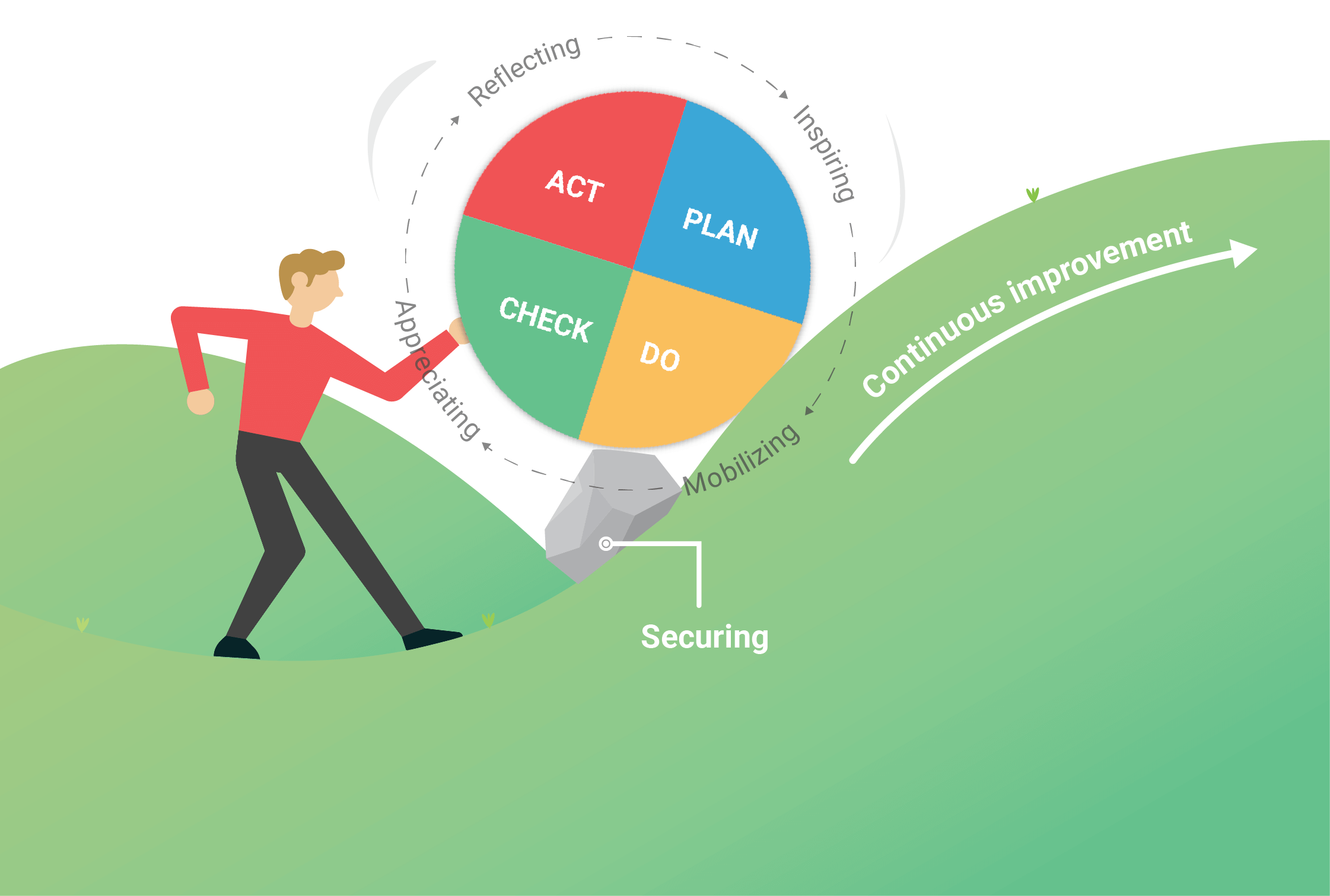

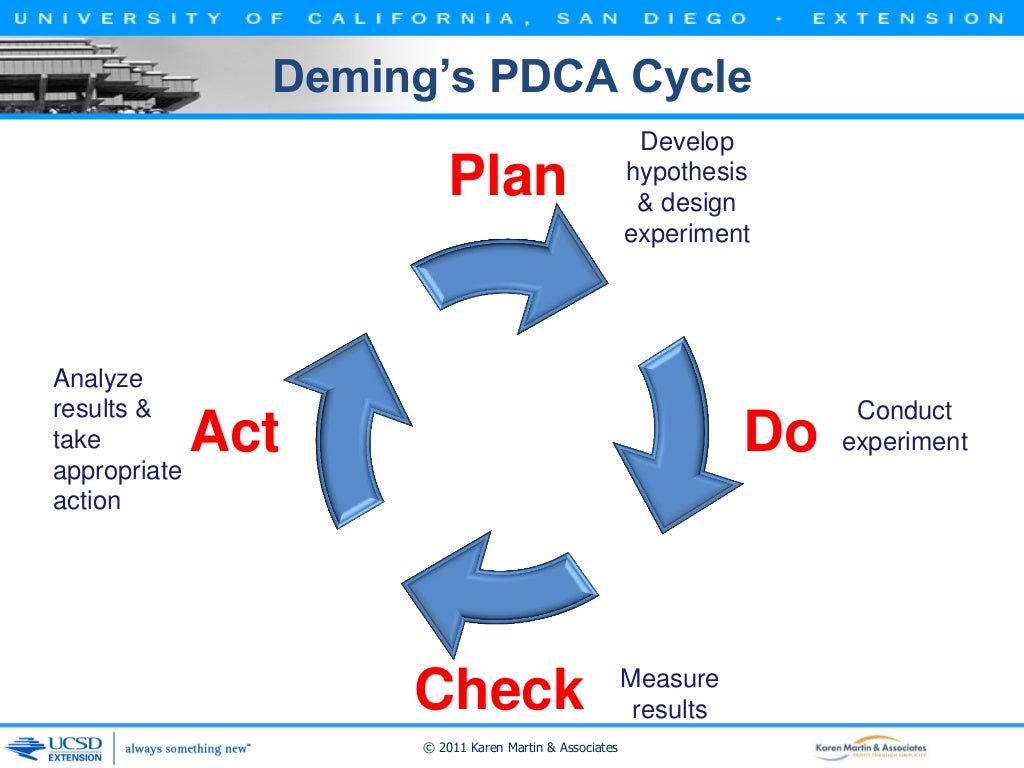

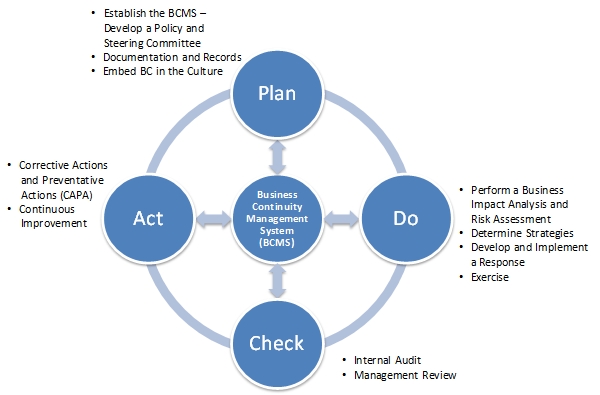

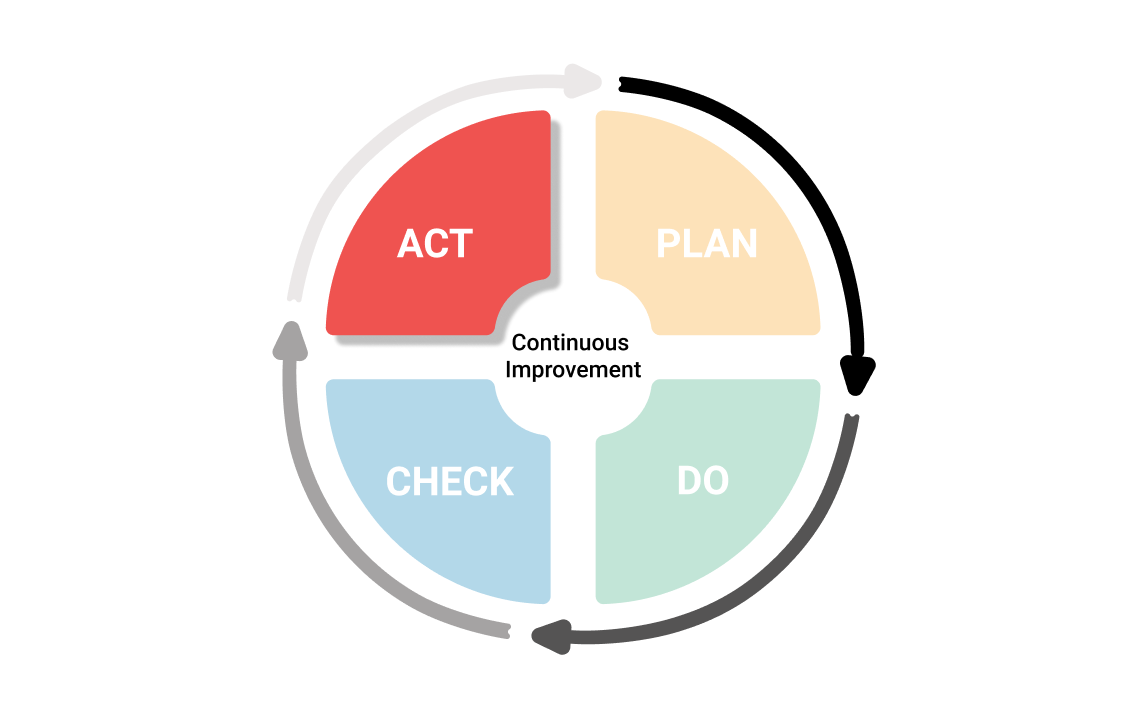

The PDCA model was developed in the 1950s by William Deming as a learning or improvement process based on the scientific method of problem-solving.

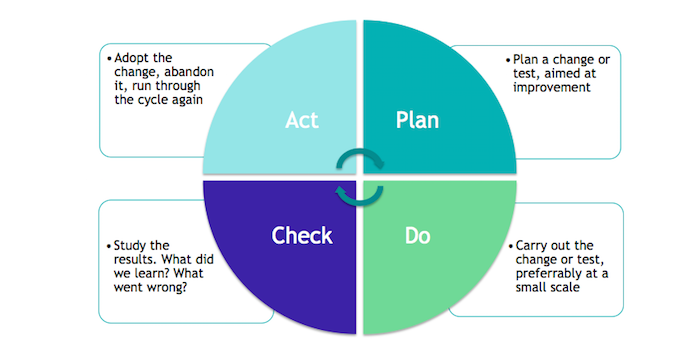

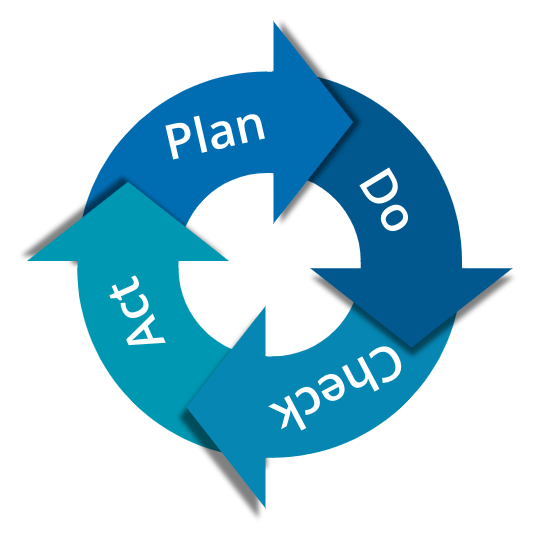

Pdca act action. Well PDCA (which stands for Plan-Do-Check-Act) is an offshoot of Lean. How to run a PDCA cycle yourself. PDCA is an improvement cycle based on the scientific method of proposing a change in a process, implementing the change, measuring the results, and taking appropriate action.

It is also known as the Deming Cycle, Shewhart cycle and Deming Wheel. Another name for the PDCA cycle is the Shewhart cycle. PDCA is the basic structure for the district’s overall strategic planning, needs–analysis, process design and delivery, staff goal-setting and evaluation.

The PDCA concept usually refers to the famous administrator who popularized it:. I know many of us have been exposed to Plan-Do-Check-Action (PDCA), (note some earlier versions from Deming the PDSA (Plan- Do-Study-Act) cycle). PDCA มีหลากหลายหลักการที่ทำให้เราไปถึงความสำเร็จที่เราตั้งใจไว้ ซึ่งถ้าลองวิเคราะห์โดยใช้หลักการ Plan – Do – Check – Act เป็นกรอบในการ.

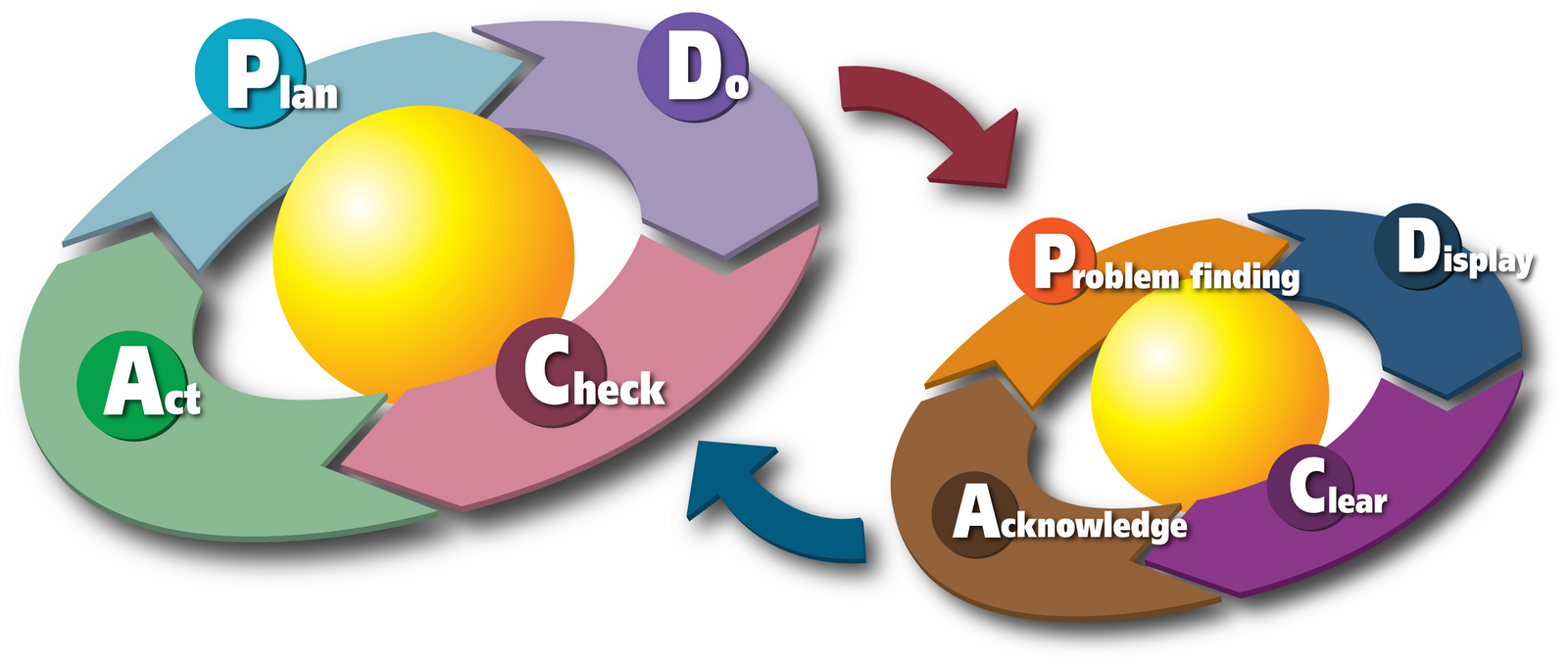

But in fact, the PDCA concept (or cycle) emerged in the 1930s, designed by American Walter Andrew Shewhart. William Edwards Deming in the 1950s (which is why it’s sometimes called the ‘Deming Wheel.’). PDSA, SDCA, OODA, ODCA, DMAIC, LAMDA, FACTUAL, Kata, and 8D – and probably more that I do not know of.

Plan, Do, Check and Act. Plan Do Check Act (PDCA) template for PowerPoint is a fully editable template based on the PDCA cycle developed by W. Welcome to the Plan-Do-Check-Act (PDCA) Tutorial Learning Objectives List the main problem solving steps of Plan-Do-Check-Act (PDCA) Identify quality improvement tools and resources for use in public health Home | Introduction to PD.

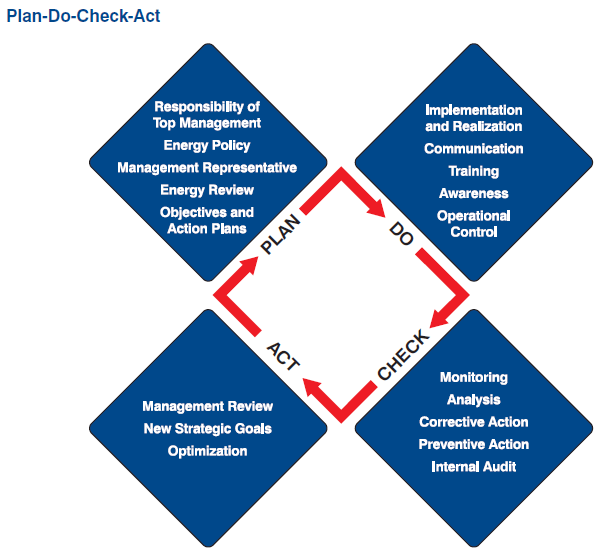

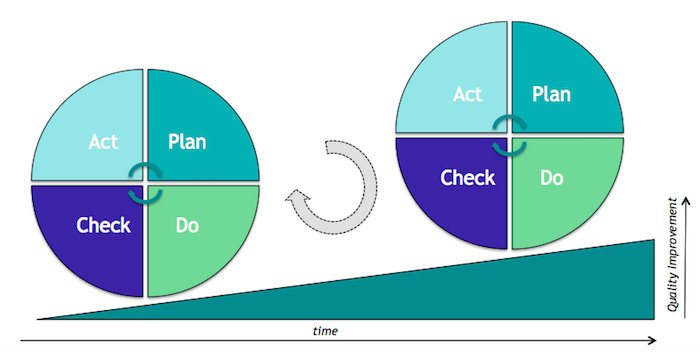

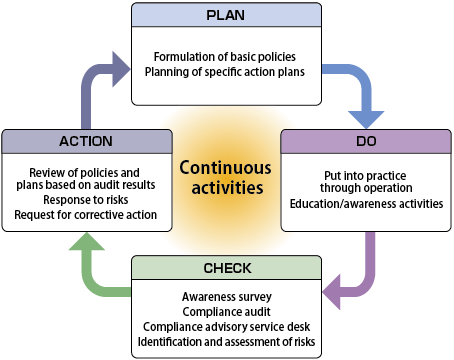

Deming was responsible for its widespread circulation which eventually got the concept to Japan where it was applied in businesses there. Plan-do-check-act, or PDCA, is a method organizations use to continually improve their internal processes, increasing the quality of their products and the overall efficiency of their business. PDCA for Quality Management entails a continuous cycle of analysis, measurement and corrective action to improve the product or process as per customer requirements.

It is one of the approaches of Total Quality Management and the base for Six Sigma's DMAIC initiative. When to Use the PDCA Cycle. The PDCA methodology is a tool designed to help in improving management, much like methodologies such as OKR and FCA.

PDCA is a continuous improvement tool that is widely used in the services and. The PDCA cycle is considered a project planning tool. Starting a new improvement project.

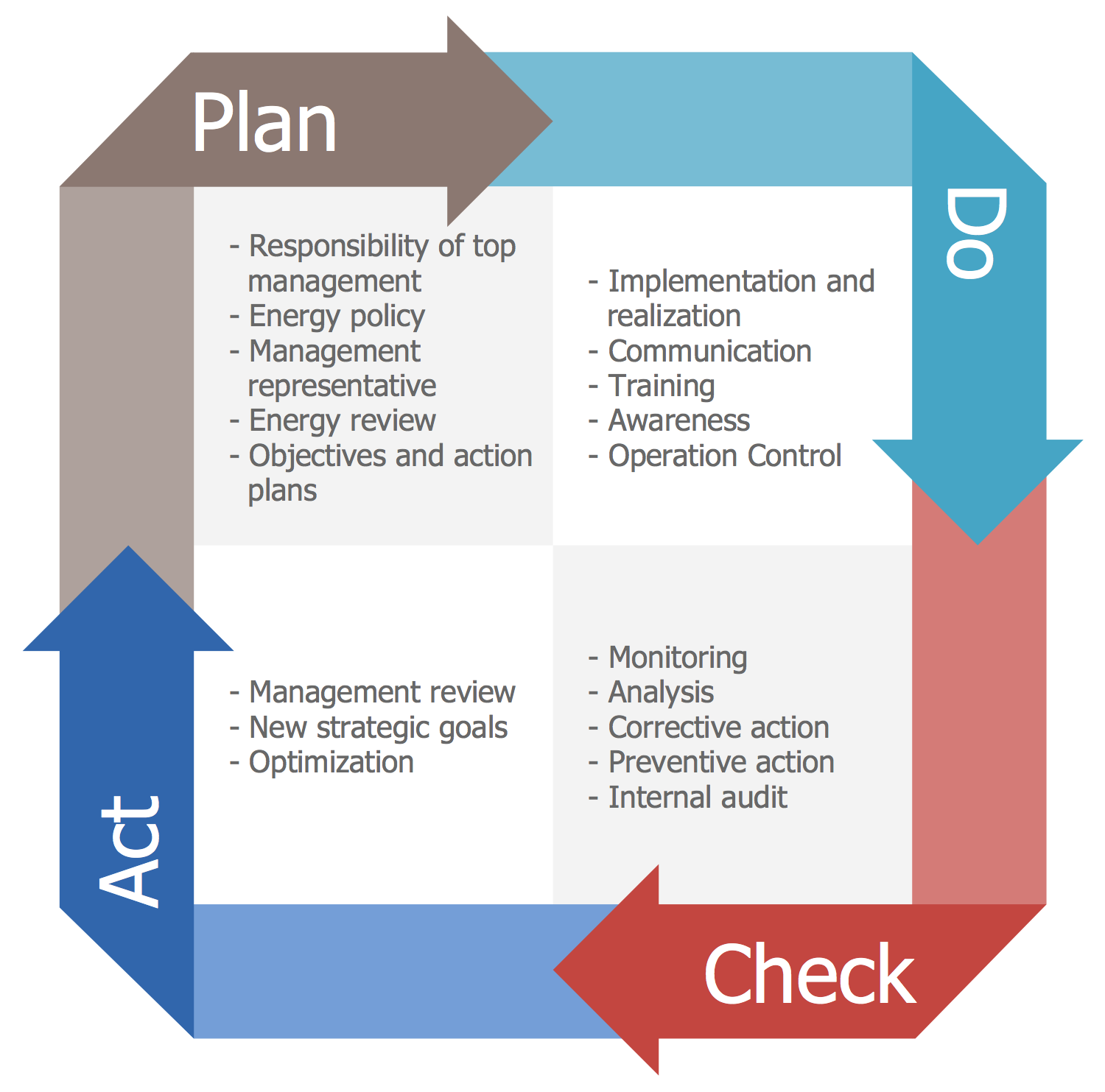

Application of PLAN DO CHECK ACT ABC Co. Pdca – act This phase is all about the actions taken to close the issues/gaps that are identified during the ‘Check’ phase. Plan Do Study Act (PDSA) Form (PDF, 971 KB, 2 pages) Practices can use this fillable Plan Do Study Act (PDSA) tool to design and test changes to improve health care quality.

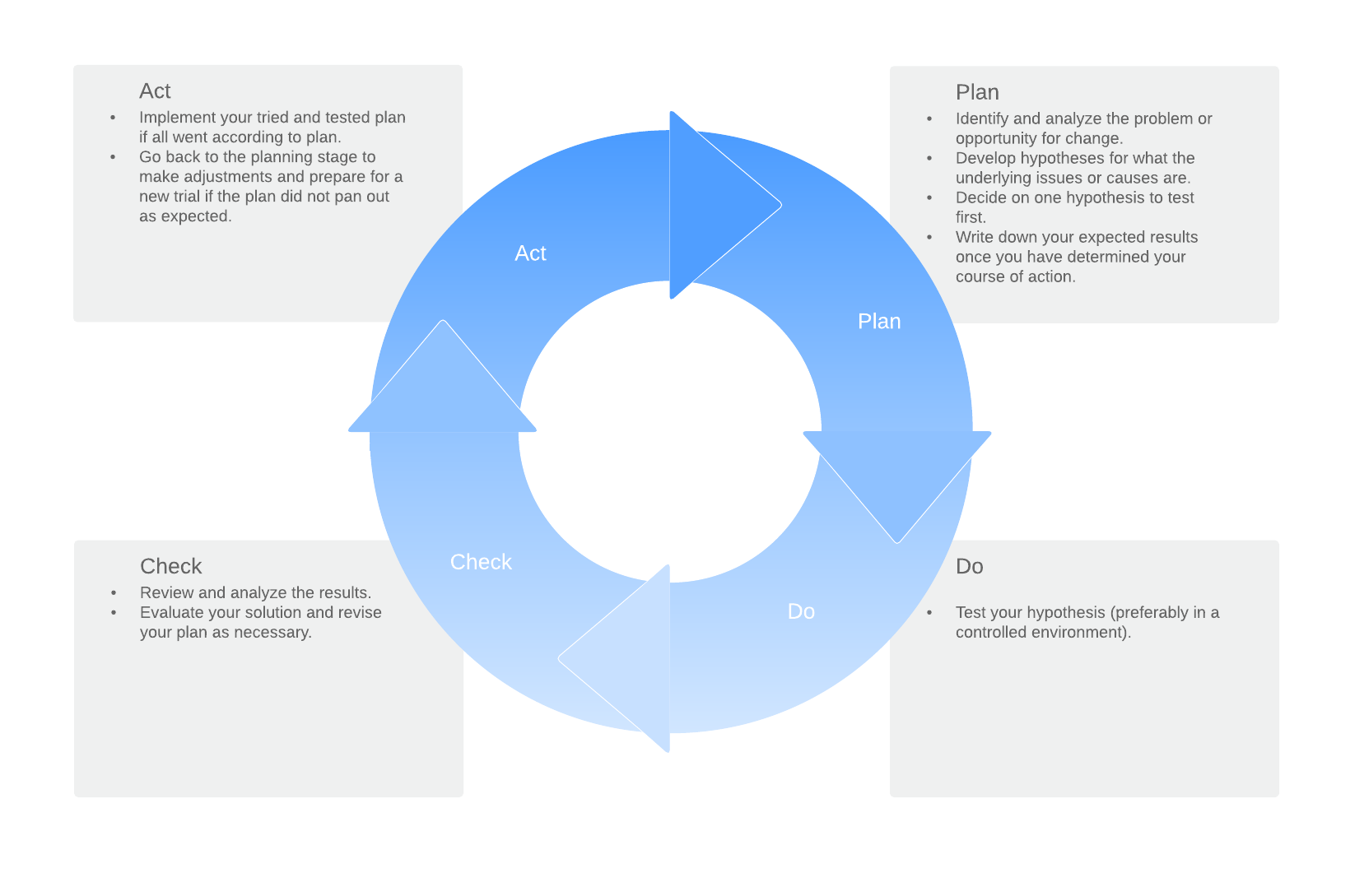

Decide on changes needed to improve the process Deming’s PDCA cycle can be illustrated as follows:. –If the change did not work, go through the cycle again. It is an essential component of lean manufacturing.

This also makes A the first step in the Continue Reading. Lean Manufacturing PDCA Deming Plan, Do, Check, Act (PDCA) The Deming Cycle Lean Manufacturing Tools and Techniques. PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products.

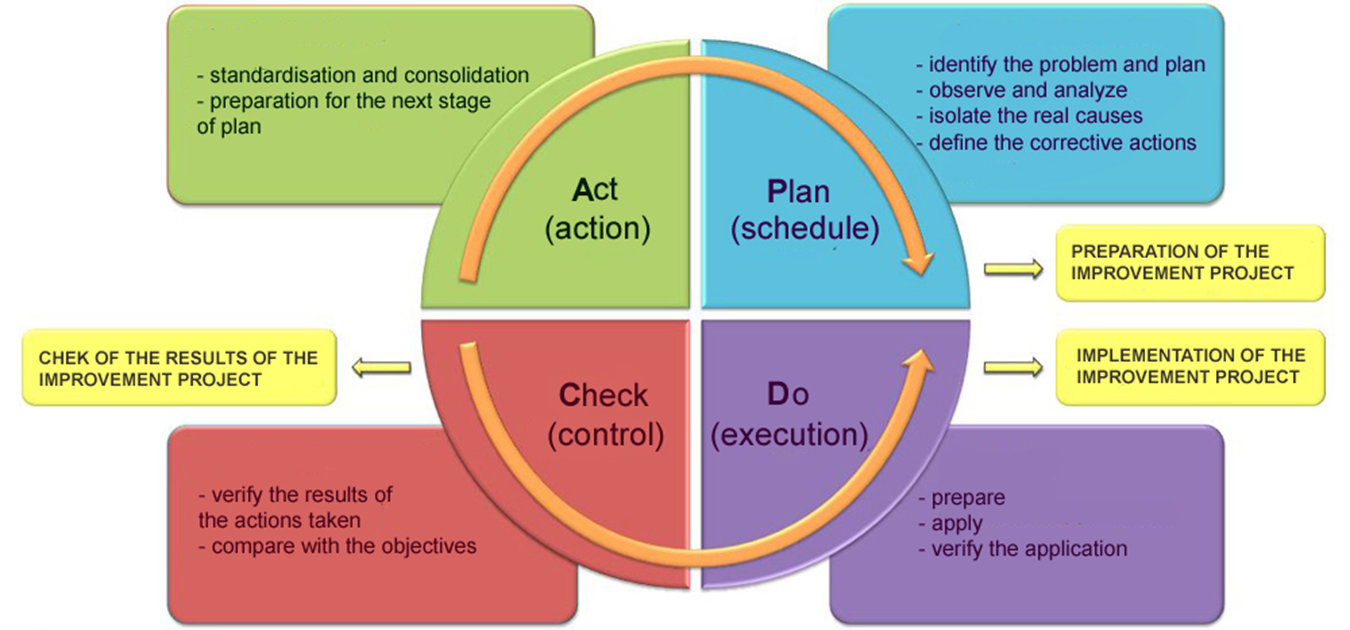

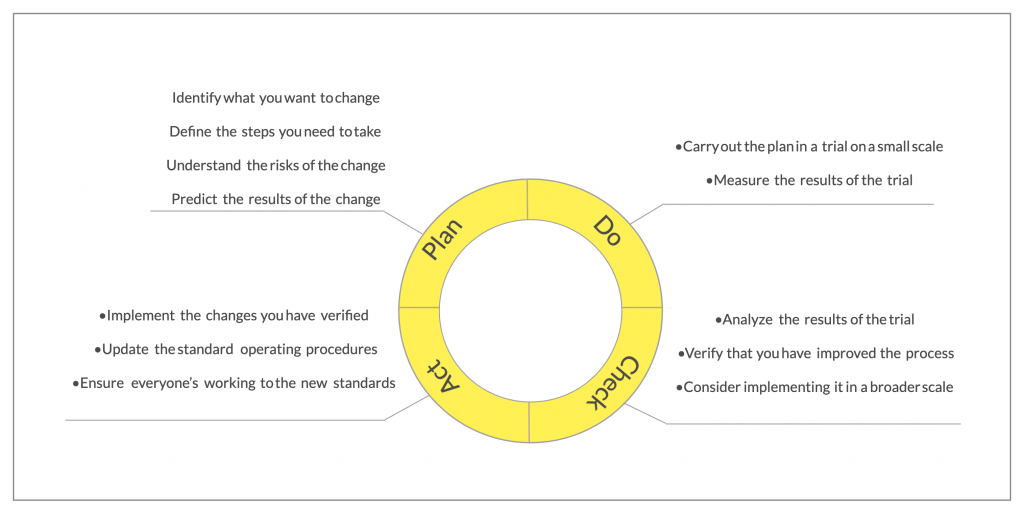

We believe, however, that the model is deficient, and that it is easy to improve it. It involves systematically testing possible solutions, assessing the results, and implementing the ones that have shown to work. Plan a change Do Test the change.

At the heart of Kaizen is the Plan Do Check Act (PDCA) Cycle. PDCA。そう、PDCAです。ビジネスマンであれば知らない人はいないんじゃないかと思うぐらい有名な改善サイクルの1つですね。 ところで、そのPDCAってなんの略なんでしょうか? 一番一般的なのは、 P:. When to use the PDCA cycle;.

Pillars explored through the Quality Storyboard methodology aim to identify problems, moving onto the designing and execution of an action plan, verification of results, and validation of a new standard to be adopted and. Use the PDCA cycle when:. A Plan-Do-Check-Act model (PDCA) or Plan-Do-Study-Act (PDSA) model can be applied to improve an overall business as well as individual projects.

PDCA's acronym's cause confusion--both "Do" and "Act" mean the same;. Here we take action on what is not working as planned. This is essentially a PDCA loop in action.

Going through the prescribed four steps guides the thinking process into breaking down the task into steps and then evaluating the outcome, improving on it, and testing again. Walter Shewhart first introduced the PDCA cycle and was later developed upon by Dr. Quality Improvement Process Using Plan, Do, Study, Act (PDSA) – Planning for Action Kathy Hybarger, RN, MSN Connie Steigmeyer, RN, MSN Betsy Lee, RN, MSPH.

During World War II. This model is also referred to as the Deming cycle, Shewhart cycle, plan-do-check-adjust, or plan–do–study–act (PDSA). Konsep siklus PDCA (Plan, Do, Check dan Act) ini pertama kali diperkenalkan oleh seorang ahli manajemen kualitas dari Amerika Serikat yang bernama Dr.

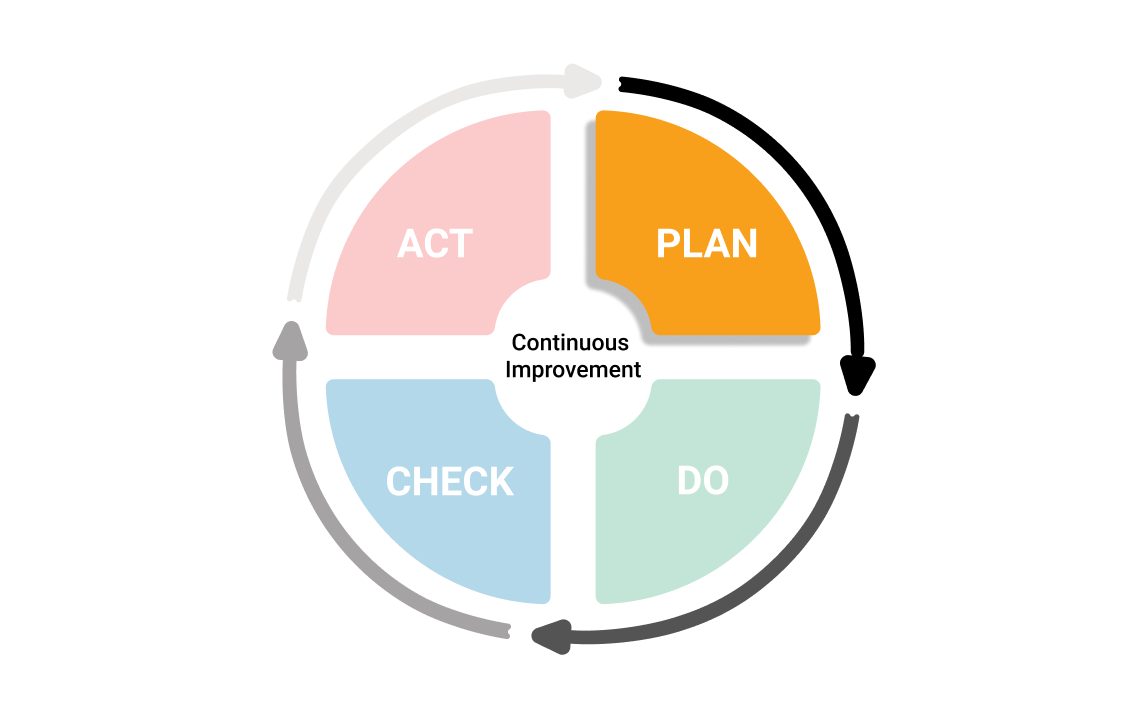

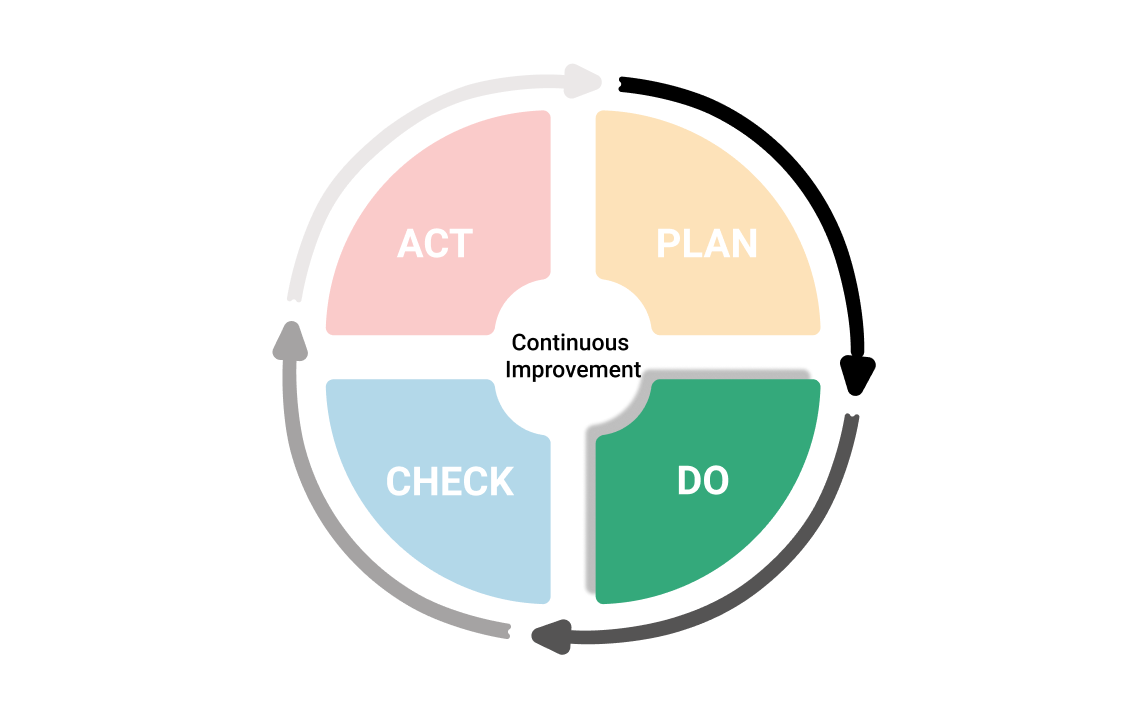

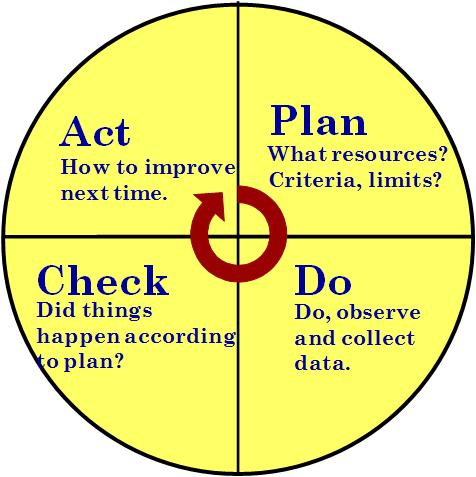

The basis of the PDCA cycle is a four-part quality lifecycle. They can provide feedback about what works and what doesn't. Central to the scientific method, problem solving and continuous improvement, the PDCA cycle stands for Plan, Do, Check, and A is for Act, Adjust or Action.

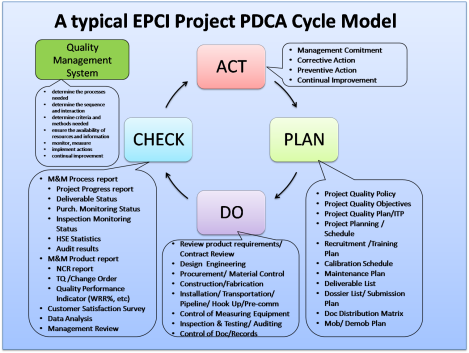

PDCA is based on the “Shewhart cycle,” and was made popular by Dr. The approach is iterative - that is, it is a cycle. Used PDCA cycle for one of their corrective action for oversize hub production from a line of automatic manufacturing machines.

Plan, Do, Check, and Act are critical for consistent implementation of successful process improvements. ¾ Avoid the common disconnects as seen by one professional in industry, such as over/under-planning and not validating the. PDCA cycle stands for the Plan-Do-Check-Act cycle and is a tool commonly used for project planning and continuous improvement.

PDCA Cycle is a continuous process until we achieve our goals which we planned. In that presentation, Deming described the continuous improvement cycle proposed by Shewhart in the 1939 book, “Statistical Method from the Viewpoint of Quality Control,” which was based on the scientific method that had emerged much earlier in the 1600’s. It is best to use the PDCA cycle when, as defined by ASQ:.

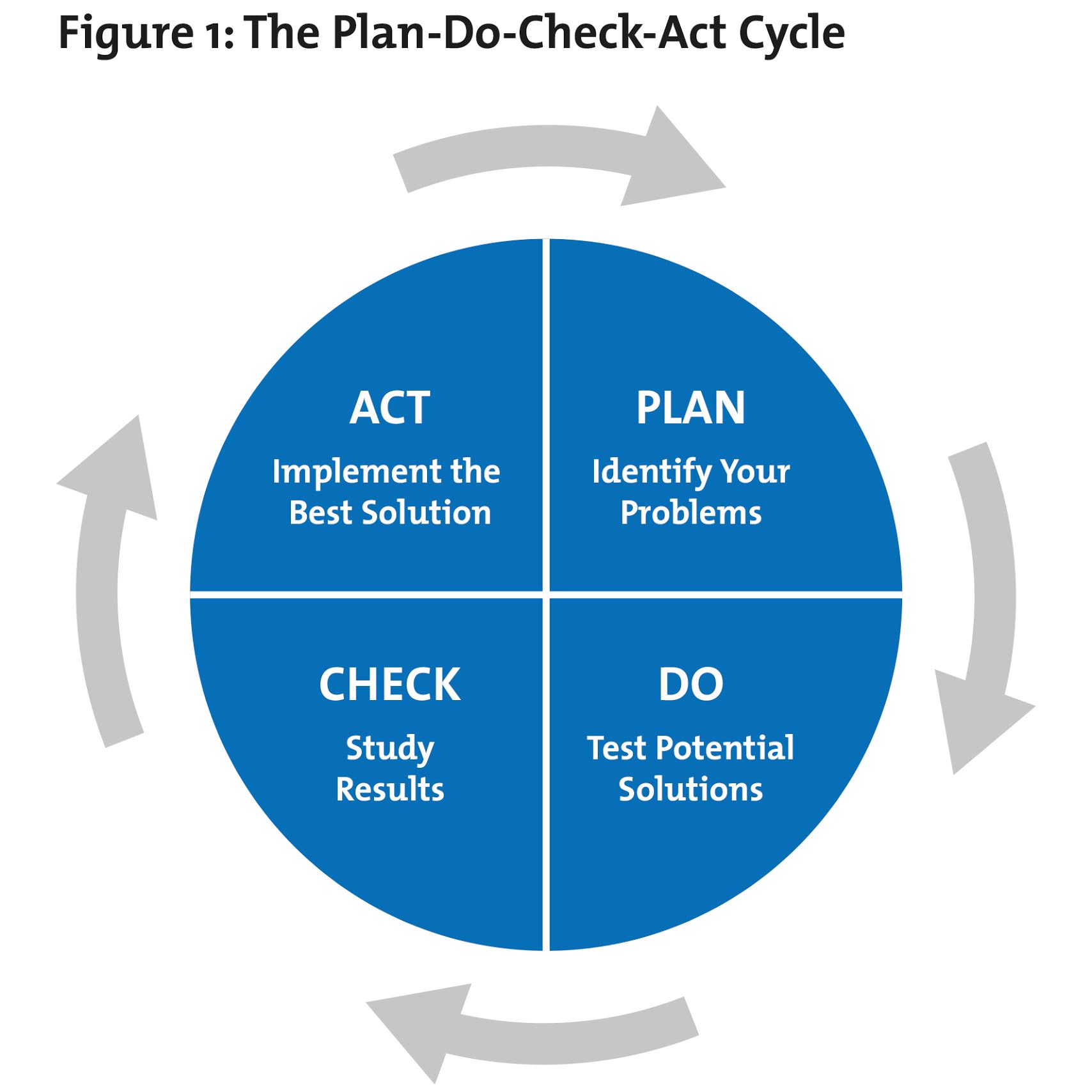

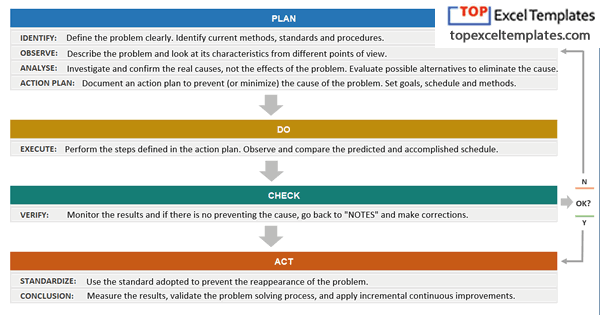

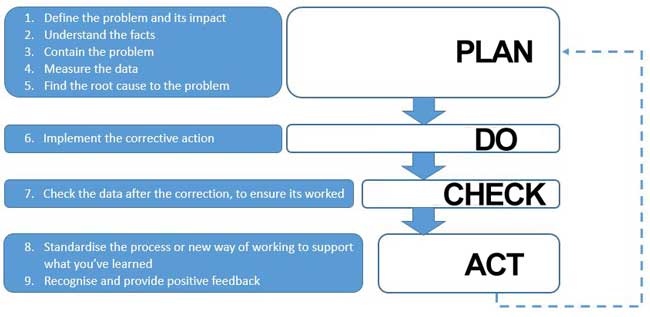

The Plan-Do-Check-Act (PDCA) Cycle is a four-step problem-solving iterative technique used to improve business processes. It was used to improve the production process in the U.S. The 4 Activities of the PDCA Cycle Plan.

Deming cycle is popularly known as the PDCA cycle, and the acronym stands for Plan-Do-Check-Act. One of the major disadvantages of the PDCA methodology is its oversimplification of the improvement process. PDCA is an acronym for a change management, and continuous improvement process.

While it was made famous by Toyota, the concept was created by legendary management consultant Dr. PDCA –A3 lean.ohio.gov PDCA Method Plan Recognize an opportunity;. Edwards Deming, considered by many to be the father of modern quality control.3 During his lectures in Japan in the early 1950s, Deming noted that the Japanese participants shortened the cycle’s steps to the now traditional plan, do, check and act.

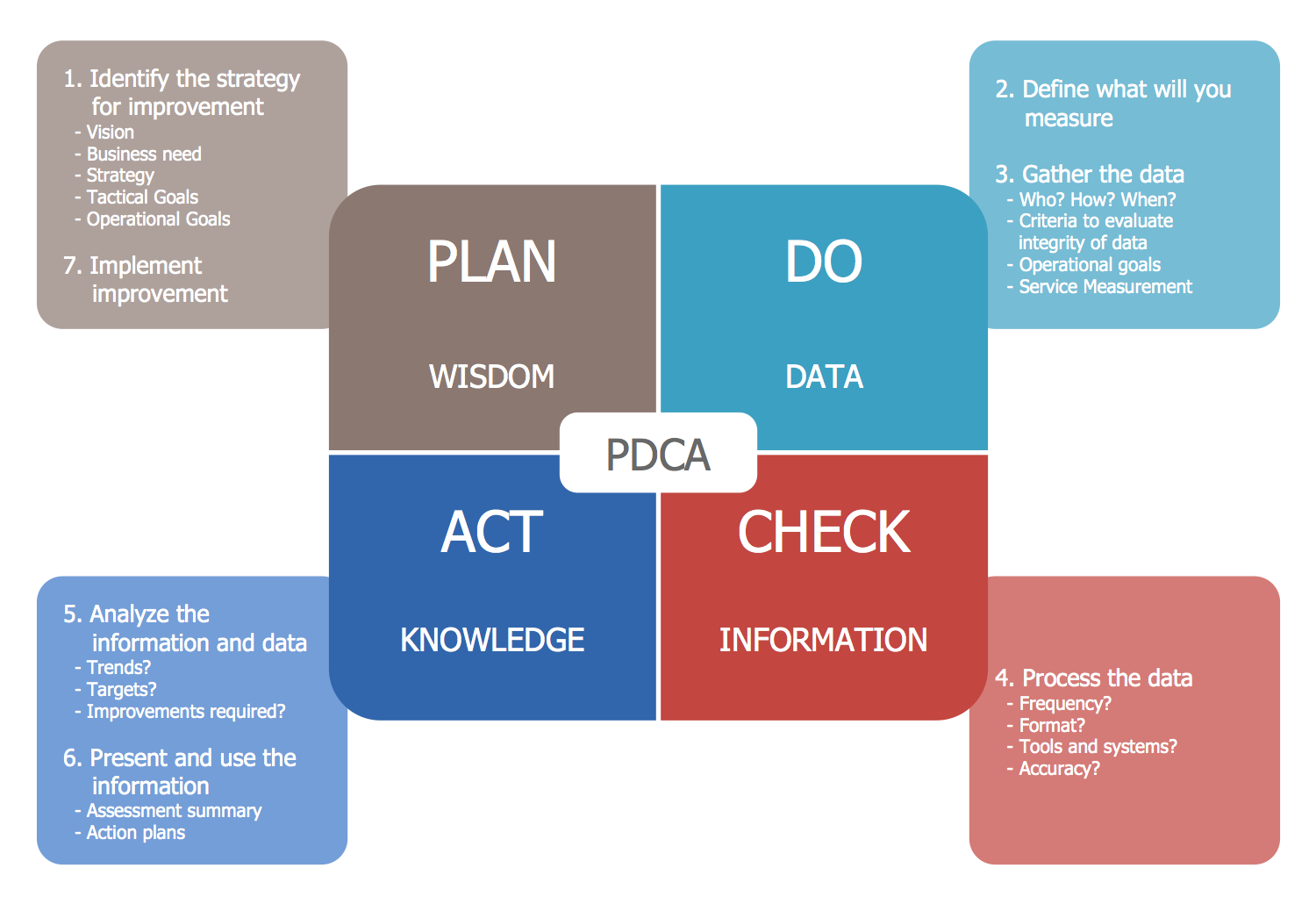

I know many of us have been exposed to Plan-Do-Check-Action (PDCA), (note some earlier versions from Deming the PDSA (Plan- Do-Study-Act) cycle).Both being a scientific, process oriented, approach. In the PDCA cycle, the work process is cyclical and supported by four pillars (Planning / Development / Check / Action). PDSA, or Plan-Do-Study-Act, is an iterative, four-stage problem-solving model used for improving a process or carrying out change.

Key performance indicators link these steps together, creating a process of continuous improvement. It is an iterative cycle which guarantees improvements for the disconnects using examples Shewart cycle (PDCA) to what is now referred to as the Deming Cycle (Plan, Do, Study, Act). It works on the improvement of activities (such as projects and processes essential to the functioning of an organization) and in solving problems, large or small, that reach these activities.

Task is to keep trying to improve the process with different plan. Using this form can be helpful to primary care practices following the Model for Improvement quality improvement approach. PDCA (Plan-Do-Check-Act) is a four-step cycle for continuous improvement.

¾ The PDCA cycle can be an effective and rapid method for implementing continuous improvement. Deming’s PDCA cycle is still the foundation of achieving success using management information, KPIs, and data analytics. PDCA stands for Plan-Do-Check-Act – a four-stage problem-solving model that enables organizations to continually improve processes, products or services.

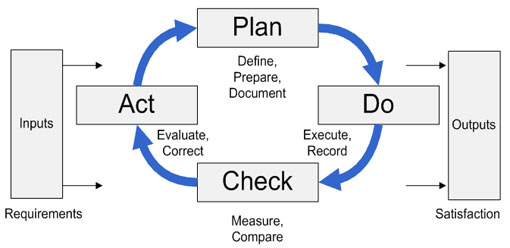

The plan-do-check-act (PDCA) cycle is an iterative and repetitive four-stage approach used in business process management for continuously improving processes, products, and services. The PDCA cycle is used in management and manufacturing. The PDCA cycle consists of four steps:.

The way it does this is through identifying errors, creating hypotheses to deal with them, testing the method, and acting on the results. In fact, the name PDCA was coined by participants of his lectures, who streamlined the Shewhart Cycle to “Plan, Do, Check, Act.” Deming actually preferred “Study” to “Check,” making it the Plan-Do-Study-Act or PDSA cycle, as the word placed more emphasis on analyzing results rather than simply checking what had changed. The Plan-Do-Check-Act (PDCA) cycle, also known as the Deming wheel or the Deming cycle, is an iterative method for continual improvement of processes, products, or services and is a key element of lean management.

It’s also the last letter in PDCA. It is during the ‘Check’ phase that the actual measurement and analysis of deviation from plan versus the records are evident during execution. It is also known as the Deming circle / cycle / wheel, the Shewhart cycle, the control circle / cycle, or plan–do–study–act (PDSA).

Plan, Do, Check, Act(ualize). PDCA (Plan-Do-Check-Act) finds widespread application as a quality management tool. It’s the first letter in the alphabet.

The Plan-do-check-act cycle (Figure 1) is a four-step model for carrying out change. Plan, Do, Check, Act. PDCA activities consist of four steps namely Plan, Do, Check, and Action with repeated stages forming like a circle.

Deming’s focus was on industrial production processes, and the level of improvements he sought were on the level of production. Both being a scientific, process oriented, approach to solving problems efficiently and effectively. When using the PDSA cycle, it's important to include internal and external customers;.

In my last posts I explained the PDCA (Plan, Do, Check, Act), common mistakes, and its history.However, there is a whole fruit stand of additional versions with some modifications that have popped up:. And these actually constitute the Acronym of the PDCA cycle:. PDCA is a common model and it is known by many people.

Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement. PDCA ("Plan-Do-Check-Act") is an iterative four step problem solving process typically used in quality control. I i 4 Key Figures in PDCA.

This cycle may be used to improve, for example, an online ordering service or the Service Level Management process within an organization. Plan, Do, Check, Act (PDCA) is a continual improvement methodology championed by one of the founding fathers of quality management, Dr. PDCA emerged from a lecture given by Deming in Japan in 1950.

Carry out a small-scale pilot Check Review the test, analyze the results and identify what you’ve learned Act Take action based on what you learned:. The Plan-Do-Study-Act (PDSA) method is a way to test a change that is implemented. The PDCA cycle is a four-step problem solving iterative technique used to improves business processes and bring about change.

This inherent fault relates to the shortcomings from adaptation of the original Japanese methodology. And PDCA's "Plan" phase includes much more than what one normally associates with the planning process. Pengertian dan Siklus PDCA – PDCA adalah singkatan dari PLAN, DO, CHECK dan ACT yaitu siklus peningkatan proses (Process Improvement) yang berkesinambungan atau secara terus menerus seperti lingkaran yang tidak ada akhirnya.

Other terms of the PDCA cycle include the Deming circle, the Shewhart cycle, the control circle, or the Plan-Do-Study-Act (PDSA) cycle.

How To Do Pdca Step By Step Everything You Need To Know

85 Plan Do Check Act Pdca Stock Photos Pictures Royalty Free Images Istock

How To Use Pdca Cycle To Improve Process Efficiency Tallyfy

Energy Management Plan Do Check Act

Pdca Cycle Plan Do Check Act Creative Safety Supply

My Pdca A Perfect Companion For All Professionals Bexsolutionz

Amazon Com Pdca Plan Do Check Act Poster 22 X 28 Made In The Usa Office Products

Q Tbn 3aand9gcqo38jcpdebvlxbrx9ir6jd0x6plhapz4dhmxnyaevvanxlccbg Usqp Cau

Implementing 5s With P D C A Cycle Download Scientific Diagram

Plan Do Check Act Pdca Model See Online Version For Colours Download Scientific Diagram

Pdca Cycle In Cycle How To Plan Business Powerpoint Templates

Plan Do Check Act Pdca Solution Conceptdraw Com

Auditing For Control And Improvement Qualitywbt

Apply The Pdca Cycle For Continuous Improvement On Epci Project Mande Blog

What Is Plan Do Check Act Pdca Cycle Kanbanize

Free Art Print Of Pdca Plan Do Check Act Business Woman Do Pdca Plan Do Check Action For Business Continuous Improvement Freeart Fa

Pdca Plan Do Check Act The Blog Of Logistics At Mgeps At Upv

Pdca The 4 Steps Of Effective Marketing By Analytics That Profit Medium

How To Apply The Plan Do Check Act Pdca Model Lucidchart Blog

How Do I Use Plan Do Check Act To Manage Safety Well

Plan Do Check Act Pdca Implementing New Ideas In A Controlled Way Colleaga

Pdca Cycle The 4 Gears Of Continual Service Improvement

What Is Plan Do Check Act Pdca Cycle Kanbanize

Pdca Cycle Example Business Process Management How To Plan Online School College

Ict Institute Information Security And Pdca Plan Do Check Act

Plan Do Check Act Pdca From Mindtools Com

Plan Do Check Act 24 7 We Never Stop Thinking Pdca 24 7 We Start With A Results Focused Purpose Driven Massive Action Plan And Push It Through The Cont

Pdca Plan Do Check Act Business Stock Photo Edit Now

How To Use The Pdca Cycle To Improve Your Business

How To Do Pdca Step By Step Everything You Need To Know

The Effectiveness Of The Plan Do Check Act Pdca Cycle

Plan Do Check Act Pdca A Comprehensive Guide Edrawmax

What Is Plan Do Check Act Pdca Cycle Kanbanize

Continuous Improvement 101 The Deming Cycle Pdca Flevy Com Blog

Pdca Wikipedia

Q Tbn 3aand9gcqw M2rspqmmc2miofhqd7sdp9zzq3cztxfztiorrrmxyz 5rjx Usqp Cau

Plan Do Check Act In The Lean Lexicon C

Plan Do Check Act Powerpoint Templates Pdca

Using Job Tasks For More Efficient Pdca Cycles

Using Plan Do Check Act Pdca To Process Teambuilding Activities How To Plan Process Control Team Building Activities

Ict Institute Information Security And Pdca Plan Do Check Act

What Is The Pdca Cycle How Does It Improve Your Management

The Key To Lean Plan Do Check Act Allaboutlean Com

Make Kpis Measurable Operationalize Kpis Kpi Pdca

The Pdca Cycle In Energy And Utilities Management Viridis

The Effectiveness Of The Plan Do Check Act Cycle Business Enterprise Mapping

Pdca Process Improvement Action Plan Strategy Colorful Rubber Band On The Black Backgrounds With Text Plan Do Check And Act Stock Image Image Of Band Backgrounds

The Humble Extraordinary Pdca The Kaizen Way

Action Plan How To Be More Effective When Managing It

Deming S Pdca Cycle Plan Analyze

What Is The Plan Do Check Act Cycle

Simple Pdca Excel Template Free Deming Cycle Spreadsheet Example

Pdca Cycle What Is The Plan Do Check Act Cycle Asq

The Plan Do Check Act Cycle Free Management Books

Q Tbn 3aand9gcr3mdu80vo4aqashuc9fdqf7vuqeiu41onm Jwnjpy2fwuqrbcx Usqp Cau

Agile Lean Approach With Plan Do Check Act Cycle

Pdca Photos Royalty Free Images Graphics Vectors Videos Adobe Stock

Pdca How To Eliminate Error In Your Processes And Products Process Street Checklist Workflow And Sop Software

Pdca In Interface Lean Analytics Association

Pdca Cycle A Comprehensive Guide To Plan Do Check Act

Plan Do Check Act A Simple 4 Step Problem Solving Methodology Educational Business Articles

16 The Principles Of Pdca Management Plan Do Check Act Usually Is Download Scientific Diagram

Pdca Plan Do Check Act Human Performance Technology Manual

What Is Plan Do Check Act How Do You Use Pdca

How To Master Iso 9001 Pdca Cycle Plan Do Check Act

Flat 3d Isometric Businessman Standing In Front Of Pdca Plan Royalty Free Cliparts Vectors And Stock Illustration Image

Plan Do Check Act Pdca Solution Conceptdraw Com

Pdca Plan Do Check Act Deming Cycle Diagram Method Infographic Royalty Free Cliparts Vectors And Stock Illustration Image

Continuous Improvement With Pdca As A Qa An Important Part Of Your Tasks By Mohammed Amine Rouh Medium

How To Apply The Plan Do Check Act Pdca Model Lucidchart Blog

Pdca Cycle The 4 Gears Of Continual Service Improvement

Pdca Cycle Process Improvement Action Plan Strategy Wooden Square On The Black Backgrounds With Text Plan Do Check And Act Stock Photo Image Of Continuous Change

Understanding The Pdca Cycle Centuryqsm

Kaizen Via Plan Do Check Act Pdca Lean Six Sigma Belgium

How Pdca Relates To Business Continuity Avalution

Pdca Plan Do Check Act Extended Diagram Karn Bulsuk Full Speed Ahead

How To Apply The Plan Do Check Act Pdca Model Lucidchart Blog

What Is Plan Do Check Act Pdca Cycle Kanbanize

Managing Inspections In Accordance With The Pdca Plan Do Check Act Method

What Is Plan Do Check Act Pdca Cycle Kanbanize

Pdca Plan Do Check And Act

Pdca Plan Do Reflect Improve Um Sorry I Mean Check Act It S A Delivery Thing

.jpg?width=516&name=PDCA%20(2).jpg)

Plan Do Check Act

Pdca Form

Using The Pdca Cycle To Support Continuous Improvement Kaizen

Plan Do Check Act Pdca Solution Conceptdraw Com

Pdca Cycle What Is The Plan Do Check Act Cycle Asq

The Four Steps Of Pdca And How They Lead To Continuous Improvement

Pdca Plan Do Check Act Template

Your Family Agile And You Pdca Psychology Continues Improvement And Kids Video Games

1

What Is The Pdca Cycle How Does It Improve Your Management

The Pdca Cycle In Energy And Utilities Management Viridis

How To Implement The Pdca Cycle Plan Do Check Act Free Template

Plan Do Check Act Cycle Source Management Systems Consulting

Pdca Wikipedia

Pdca Cycle Process Improvement Action Plan Strategy Wooden Square On The Black Backgrounds With Text Plan Do Check And Act With Copy Space Stock Photo Alamy

Pdca Cycle A Comprehensive Guide To Plan Do Check Act